To meet a wide range of technical, operational and economic requirements of consumers in various industries, four types of elastic plate couplings have been developed and are being commercialized. In the given below table list you can find their main features and characteristics, allowing you to choose the best option for each case.

Comparative characteristics of elastic plate couplings of various types

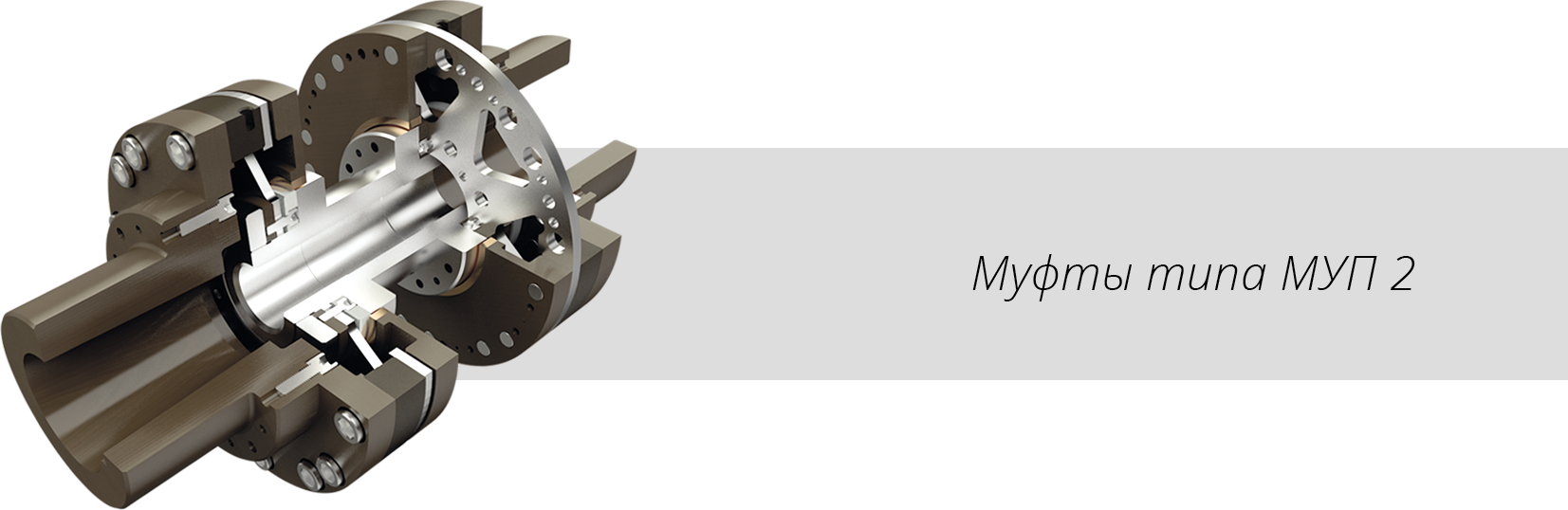

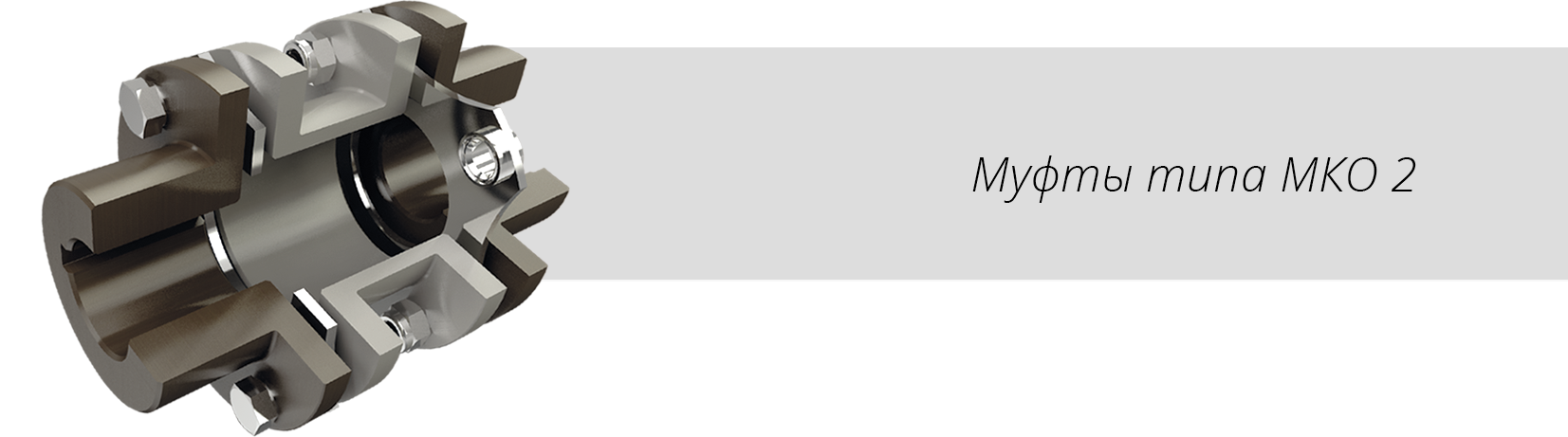

| Coupling types | MKO | MK | MKS | MUP |

| coupling kompensiruyuschayaoblegchennaya |

coupling compensating |

coupling compensating special |

coupling elastic plate |

|

| Typical application area | General technical application in the absence of special requirements |

Equipment for the petrochemical, oil and gas industries in explosive areas |

Used in units with a small distance between the ends of the connecting shafts | Used in critical machines and units of the oil and gas industry and nuclear energy |

| Compensation of radial and angular displacement of shafts | Effective | |||

| Type of elastic element | "Annular" | "Disk" | ||

| Characteristic for the emergency destruction of elastic elements |

Short Transmission Torque |

Shaft disconnection |

||

| Sparking Protection | - | + | ||

| Sparking "protection" spacer | + | |||

| Possibility of execution according to API 671 / ISO10441 | - | + | - | + |

| "Cartridge" design | - | + | - | + |

| Possibility of execution of OPB-88/97, NP-001-97 (PNAEG-01-0111-97) | - | + | - | + |

| Electrically insulated design | - | + | - | + |

| Optimization criterion | price, mass | Quality, price | Small distance between the shafts | Reliability |

| Relative (specific) price | 1 | ~1,4 | ~2 | ~2 |